Cutouts are fun. A circular business card, star-shaped sticker or a life-size cutout of your dog are going to be much more memorable and interactive than other print products.

Traditionally…

…shapes were created on a letterpress using a particular die (also known as “die line”).

Once you have a die, or a physical template that ensures proper layout for a printed product, you can begin to create multiple die cut products.

Today…

…there are several methods of creating cutouts. In addition to our 1971 Heidelberg Windmill, we create cutouts on our Colex Digital Flatbed Cutter.

Although we will tell you which machine is best to use for your particular project, it can be useful to know their differences.

Cutout Difference 1: The Colex is better suited for wide-format projects.

As you can tell from the above images of the machines, the Colex is a lot bigger than the Heidelberg. The letterpress can only print items as large as 10″x 15″, while the Colex can print up to 150″.

The Colex can print both small- and large-format items. This is the main difference between the two machines, and if you take anything away from this blog post, it should be this point.

Cutout Difference 2: The Colex is better suited for short-run projects.

Although both machines can do both short- and long-run, the Colex is better for short-run. It takes about three days to create a physical die for the letterpress, while the Colex can create cutouts in one day. Thus, if you need to print hundreds of cutouts, go with the Colex. If you need thousands, go with the letterpress. Furthermore, if you are going to be printing the same cutout multiple times (say, you need the same sticker every year), it is better to cut on the letterpress. We save and store each die, making the second and third run easier than the first.

Cutout Difference 3: The Colex can cut any material.

The letterpress can only cut certain, relatively thin, materials. The Colex can cut foamboard, wood, acrylic and other thicker substances that the letterpress cannot.

Cutout Difference 4: The letterpress is better with paper.

As we mentioned above, the Colex is better at cutting thick material. Paper, especially, can be almost too thin for the Colex to cut, and it can tear easily. If you need paper cutouts, it is best to cut on the letterpress.

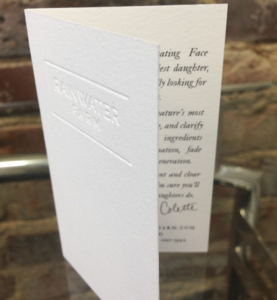

Cutout Difference 5: The letterpress can emboss and deboss.

If you would like to add a nice touch (literally) to an invitation, business card or stationery, you can choose to emboss or deboss words or images. Embossing or debossing is either raising or depressing, respectively, certain aspects of a print product.

Cutout Difference 6: The letterpress is better at small, hard angles.

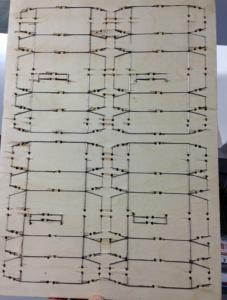

Although the Colex can create small-format cutouts, it is better suited for wide-format projects. Thus, sometimes very small, hard angles are difficult for the Colex, such as the image below:

As you can see, the angles between each leaf are very small and sharp. Thus, this print project was cut out on the letterpress. But make no mistake — the Colex is pretty darn good at cutting precise shapes. Just take a look at the cutout of Tennessee below cut on the Colex:

Hopefully, this post has given you a better understanding of the differences between a letterpress and a Colex. We (and other printers) will always point you in the right direction, but it’s good knowledge to have walking into a print shop!

Now are you ready to make some super cool cutouts?