How to Format the Best Brochure for Your Business

Brochures may seem like an outdated way to convey and share information, but they actually serve a very important purpose. Brochures are like a business card for your organization. They are a condensed version of your organization’s story, their mission, goal, services and vision. Brochures can put your organization on the map by providing another medium for you to stand out from the rest. It can be overwhelming while designing your brochure. Your organization does a lot! What do you include? How should it be laid out? How do you make it original and unique? AMP has the resources and skills to make successful, memorable brochures, making us perfect to collaborate with. While you brainstorm and get together ideas for what you want to see on your brochure, keep these tips from Creative Market in mind to ensure a solid start to your design process.

Know your audience. Are they prospective clients? Potential new hires? Interested citizens and activists? Be sure to identify whose hands this brochure is going to end up in. This is important because it influences what information you should provide on the brochure and how you should present it so that it resonates with the reader.

Refrain from a multitude of fonts. Keeping it uniform and simple is a recipe for a clean and clear brochure. It’s fun to play around with different fonts and font sizes, but when it’s printed out and in your hand, it tends to look unprofessional and clustered. Not to mention, it takes away from your content.

Be concise. This Creative Market article reminds us that “it’s a brochure, not a book.”

Try to be very deliberate in what you decide to include on your brochure. Quality over quantity! You don’t want to overwhelm the reader with all there is to know about your organization. Share what needs to be shared and what will stick with the reader the most.

There is no need to flex your vocabulary! Use straight-forward wording. Big words can often look out of place in a limited content brochure. They give off a “trying too hard” vibe. You want to represent a credible and direct reputation with your audience.

Include a call to action. A brochure for a non-profit or any kind of interactive organization can really benefit from including a call to action. This increases the chances of the reader remembering and participating in the organization. It also builds camaraderie right off the bat with your audience, which is great —especially if that is part of the reason they are receiving the brochure in the first place!

Have a design in mind? Let us help you print! Put in an order today.

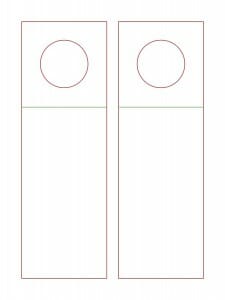

Create your own custom-printed tabs

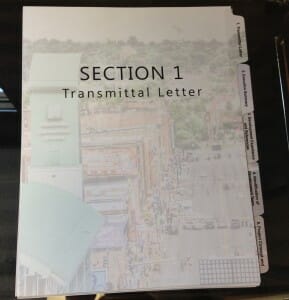

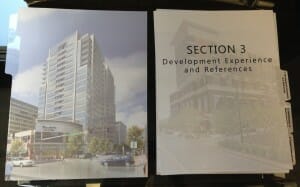

Custom-printed tabs scream organization. With school and a new work year just around the corner, custom-printed tabs will make you (and your company) look and feel more professional.

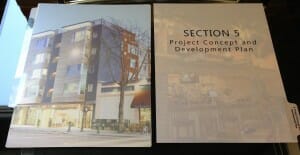

For example, if you are pitching a development plan, you are going to be taken more seriously if the proposal is organized with custom-printed tabs.

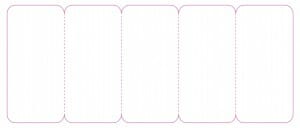

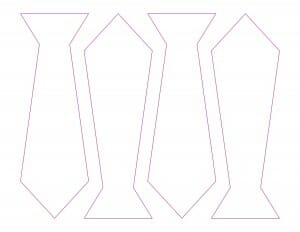

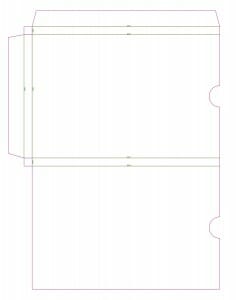

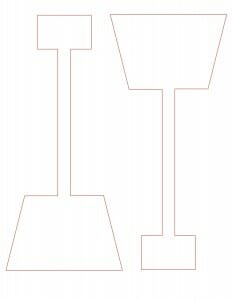

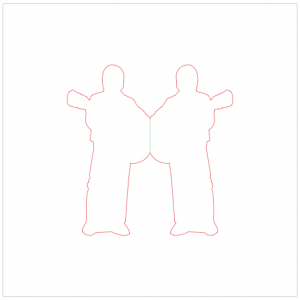

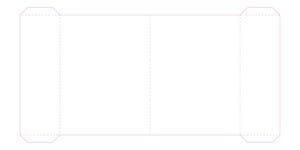

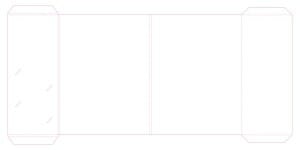

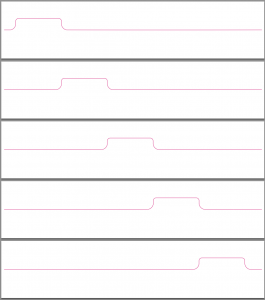

Now compare the above tabs with these:

If you are competing with another developer, which pitch do you think will stand out? The one with custom-printed tabs, of course! We can print (black ink) text on Avery plain tab dividers on our copier, which is our most affordable option. However, we really recommend color because of the reasons stated above.

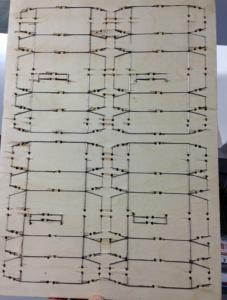

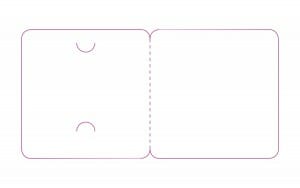

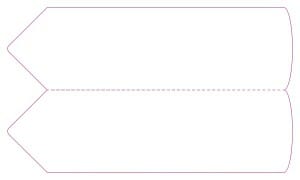

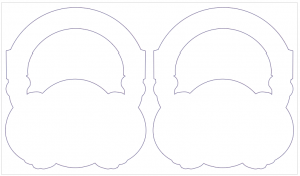

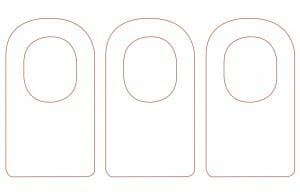

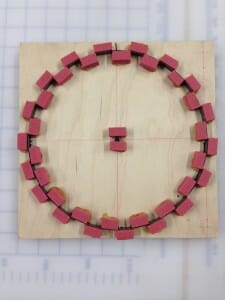

To print tabs with color, we use our tab machine. It can print tabbed-pages up to 15 inches tall with as many banks as you would like. Our standard banks are square with round corners, like the ones shown below:

Most people prefer their banks to be on the right-hand side of the pages, but some prefer their tabs on the top. Our machine can do this, too.

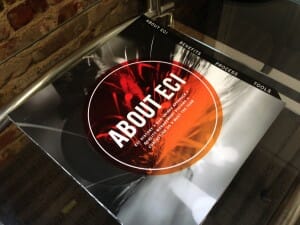

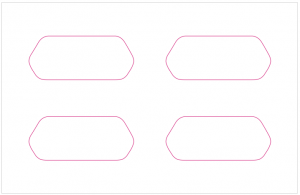

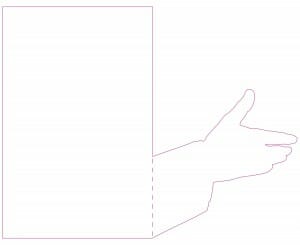

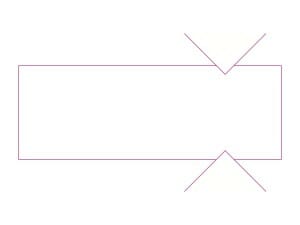

We can also create custom-shaped banks on our letterpress. For example, this company wanted tabs with a cut bottom corner. Since we already have this die made, if you would like this style of tabbed-pages, it would be cheaper than creating and ordering a new die.

Your most affordable option will be Avery plain tab dividers with black ink on our tab machine.

Custom-printed tabs serve the same purpose as customized business cards, stationery and other paper products: it makes your brand stronger. The more customized your products are, the more recognizable your brand becomes, and the more likely people are to use your brand, as people tend to use brands they recognize. If you are a student, custom-printed tabs are great for organizational purposes. Color, especially, makes tabs and information easy to find.

Want a quote on your own custom-printed tabs? Call amp today!

Cutouts: Colex or Letterpress?

Cutouts are fun. A circular business card, star-shaped sticker or a life-size cutout of your dog are going to be much more memorable and interactive than other print products.

Traditionally…

…shapes were created on a letterpress using a particular die (also known as “die line”).

Once you have a die, or a physical template that ensures proper layout for a printed product, you can begin to create multiple die cut products.

Today…

…there are several methods of creating cutouts. In addition to our 1971 Heidelberg Windmill, we create cutouts on our Colex Digital Flatbed Cutter.

Although we will tell you which machine is best to use for your particular project, it can be useful to know their differences.

Cutout Difference 1: The Colex is better suited for wide-format projects.

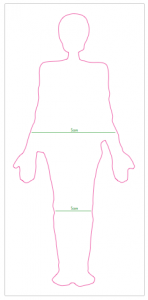

As you can tell from the above images of the machines, the Colex is a lot bigger than the Heidelberg. The letterpress can only print items as large as 10″x 15″, while the Colex can print up to 150″.

The Colex can print both small- and large-format items. This is the main difference between the two machines, and if you take anything away from this blog post, it should be this point.

Cutout Difference 2: The Colex is better suited for short-run projects.

Although both machines can do both short- and long-run, the Colex is better for short-run. It takes about three days to create a physical die for the letterpress, while the Colex can create cutouts in one day. Thus, if you need to print hundreds of cutouts, go with the Colex. If you need thousands, go with the letterpress. Furthermore, if you are going to be printing the same cutout multiple times (say, you need the same sticker every year), it is better to cut on the letterpress. We save and store each die, making the second and third run easier than the first.

Cutout Difference 3: The Colex can cut any material.

The letterpress can only cut certain, relatively thin, materials. The Colex can cut foamboard, wood, acrylic and other thicker substances that the letterpress cannot.

Cutout Difference 4: The letterpress is better with paper.

As we mentioned above, the Colex is better at cutting thick material. Paper, especially, can be almost too thin for the Colex to cut, and it can tear easily. If you need paper cutouts, it is best to cut on the letterpress.

Cutout Difference 5: The letterpress can emboss and deboss.

If you would like to add a nice touch (literally) to an invitation, business card or stationery, you can choose to emboss or deboss words or images. Embossing or debossing is either raising or depressing, respectively, certain aspects of a print product.

Cutout Difference 6: The letterpress is better at small, hard angles.

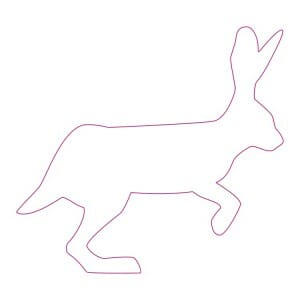

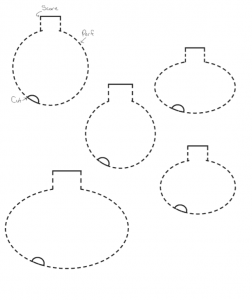

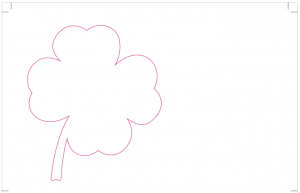

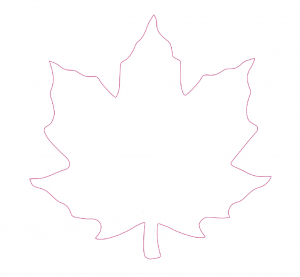

Although the Colex can create small-format cutouts, it is better suited for wide-format projects. Thus, sometimes very small, hard angles are difficult for the Colex, such as the image below:

As you can see, the angles between each leaf are very small and sharp. Thus, this print project was cut out on the letterpress. But make no mistake — the Colex is pretty darn good at cutting precise shapes. Just take a look at the cutout of Tennessee below cut on the Colex:

Hopefully, this post has given you a better understanding of the differences between a letterpress and a Colex. We (and other printers) will always point you in the right direction, but it’s good knowledge to have walking into a print shop!

Now are you ready to make some super cool cutouts?

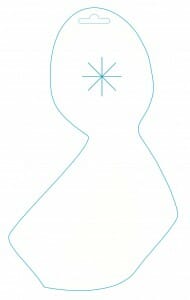

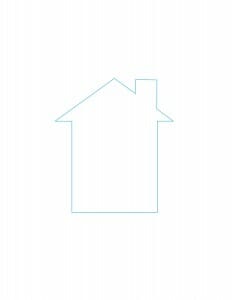

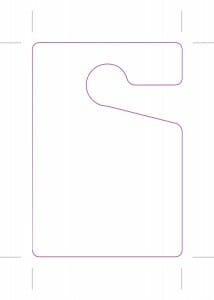

Die Cuts: amp’s Die Inventory

As most of you know, die cuts are just a fancy print term for “cut outs” or shapes. An encyclopedic definition of die cutting would be: a process used in many different industries to cut a thin, flat material into a specific shape using a steel cutting die. We mostly die cut paper and stickers at amp. The benefits of die cutting include visual appeal and a good marketing technique. A fun shape will have a lingering impression on the viewer, making you or your company stand out.

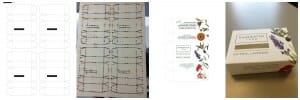

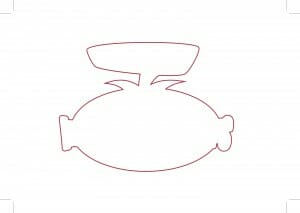

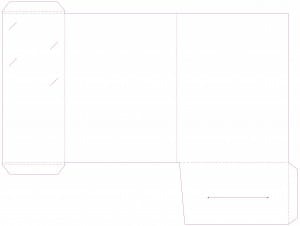

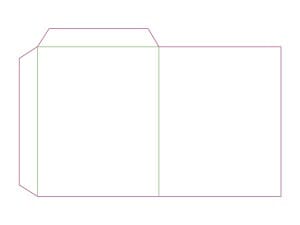

To create die cuts, you must first have a “die” or “die line:” a template that ensures proper layout for a printed product. A graphic designer can create the die line on the computer first and transfer the shape to a physical die. Below are 4 images of the process: the first is a digital picture of a soapbox die, designed on the computer. The second and third images are the physical die and a paper piece stamped out on the letterpress. The last image is the finished product, a beautifully assembled soap box.

Click to enlarge.

At amp, we use a 1971 Heidelberg Windmill to die cut. We also refer to it as our letterpress.

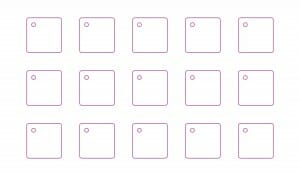

Because die cutting is a specialty that requires more set-up and finishing, it is a bit more costly. However, if a print shop already has a die made that you like, your project’s cost and time decreases. For this reason, we have made you an inventory of the dies we house at amp. This is not a complete list, as we have several company-specific dies, but it is a good start if you are looking for basic shapes. We will continually update this blog so that you always have the most up-to-date information.

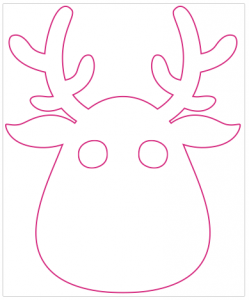

Die Cuts: Animal Dies

Die Cuts: Badge Dies

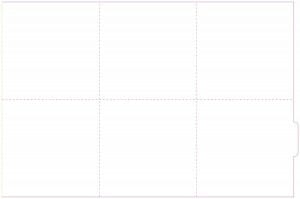

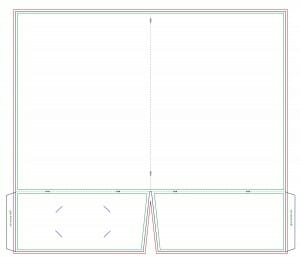

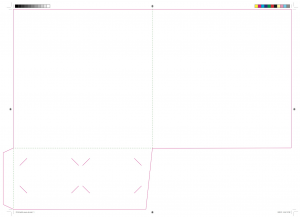

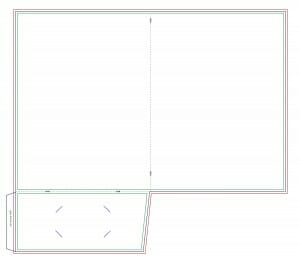

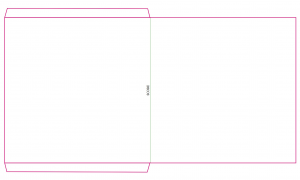

Die Cutting: Brochure Dies

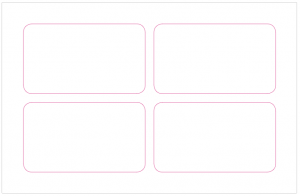

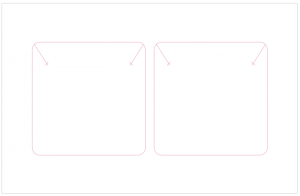

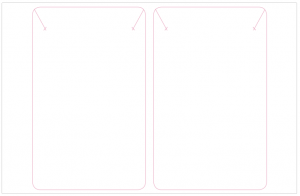

Die Cuts: Business Card Dies

Die Cuts: Card Dies

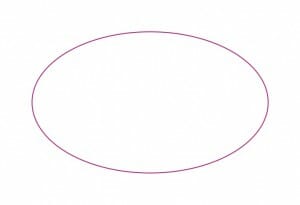

Die Cuts: Circle Dies

Die Cuts: Food and Drink Dies

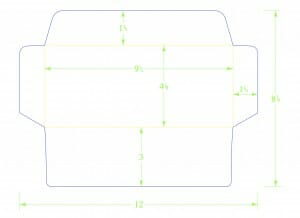

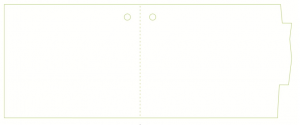

Die Cuts: Envelope Dies

Die Cuts: Fan Dies

Die Cuts: Gift Card Dies

Die Cuts: Holiday and Seasonal Dies

Die Cuts: Households and Household Items Dies

Die Cuts: Mailer Dies

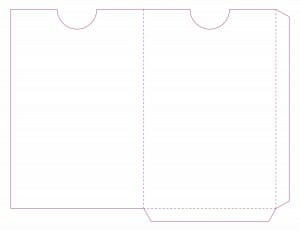

Die Cuts: Media/Press Kit Covers Dies

Die Cuts: Miscellaneous Dies

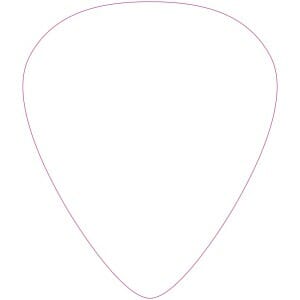

Die Cuts: Music-Related Dies

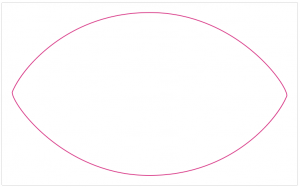

Die Cuts: Oval Dies

Die Cuts: Pocket Folder Dies

Die Cuts: Sleeve Dies

Die Cuts: Sports Dies

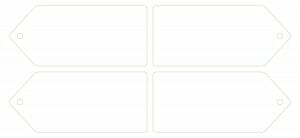

Die Cuts: Tab Dies

Die Cuts: Tag and Ticket Dies

An example of how this ticket looks with design:Die Cuts: Triangle Dies

Don’t see anything here you like? Ask us! We may have that die in-house. Again, this list is not comprehensive. If we don’t have the die, we can always make it!

Happy die cutting!

– Your friends at amp

Business Card How-To

Have you ever read a blog post about business cards that stated the obvious? Such as “put all your information on your card,” or “don’t use ugly colors?” Well, we have. Here’s what we have to say to those blog posts: duh! So we wanted to create a more descriptive, specific blog post about creating both unique and print-ready business cards.

Step 1: Business Card Design

When you design a card, make sure the images, logos and other information are located at least 1/8 inch away from the edges of the card. The cutting process is not exact, and you would not want any artwork or text trimmed.

On that same note, make sure your card has bleed. Bleed is a term used to describe documents that have images or elements that touch the edge of the page, extending beyond the trim edge and leaving no white margin.

If you use a picture, make sure the resolution is at least 300 dpi. Even if your photo looks fine on the screen, it may look blurry or fuzzy when printed.

Know the difference between color components used by computer screens and printers. Screens use a red, green and blue color scheme and mix these colors to create other colors. Printers either use CMYK or PMS. CMYK stands for cyan (blue), magenta (red), yellow and black. PMS (Pantone Matching System), or spot colors, are pre-mixed with existing and published color formulas instead of simulating colors by combining primary colors. Most printers use CMYK, so your best bet is to create your design in CMYK colors.

Step 2: Business Card Paper

When it comes to paper, the first thing to know is cover weight versus text weight. For business cards, you always want cover weight. Text weight is much thinner, and it is used for things such as pages in a magazine.

Within cover weights, there are hundreds of papers to choose from. Hundreds. Want a basketweave, woodgrain or houndstooth paper for your card? They exist. How about an astro metallics palm tree green paper for your card? Or a paper with gold specks? You can search the internet all day for different paper types in different colors. However, unique papers typically cost more and take more time to produce. So if time and budget are not factors in your decision, go for a unique paper!

Most people, however, choose from a select few types: uncoated, silk, gloss, felt, matte and linen. Sometimes uncoated, silk and gloss are lumped into one category called “smooth.” Again, there are hundreds of different colors, but most people go with white or natural. Natural is more of an off-white, as you can see below.

What’s the difference between matte and glossy? Matte has a silky and smooth surface but not the shine of the glossy business card paper. Gloss is good for cards that have a photo as it really makes the picture pop.

Step 3: Business Card Weight

Once you’ve selected the type of paper you want, you need to decide the weight of the paper. The thicker the paper, the sturdier and more professional it’s going to be. Most print shops use 80-lb cover paper as the standard because it’s cheaper. As a general rule, you should not use paper that is less than 80 lbs. We actually use 100-lb paper as the standard business card paper, despite its price, because we think it looks and feels better. The heaviest weight we own is 130-lb paper, although you can “sandwich” papers for an even thicker card. A cool way to make your card stand out is to sandwich a different colored paper between your selected paper, as shown below. The result is a thick, unforgettable business card.

Step 4: Business Card Finishing Options

Here’s where things get fun. There are 6 main types of finishing (7 if you count uncoated) which are not mutually exclusive: embossing and debossing, foil stamping, UV coating, lamination, die cutting and folding. Uncoated means simply no finishing at all. If you want to save money, you might give thought to an uncoated business card.

1. Embossing and Debossing:

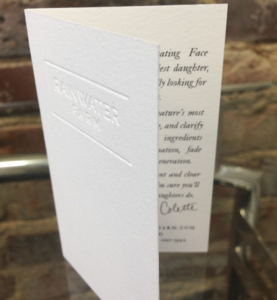

Embossing and debossing, in addition to being one of our favorite types of finishing, are two techniques used to imprint impressed or depressed images onto paper, respectively.

Embossing and debossing are used frequently for wedding invitations because they create a very elegant look and feel. The unique touch makes your brand (and you) more memorable because it triggers a different sense in the recipient. The same goes for textured paper or soft-touch lamination. Once you decide to emboss your business card, you then need to decide if you want it “blind embossed,” or left plain, as shown in the picture above. If you want to make the imprint even more memorable, you can add ink or foil stamping.

Embossing and debossing are two of the most expensive finishes because they require a die. Similar to a mold, a die is a specialized tool used to cut or shape material mostly using a press.

We use a 1971 Heidelberg Windmill to die cut all of our materials.

Embossing is slightly more expensive than debossing because it requires two dies — a male and a female die, or one that is recessed and one that is raised.

2. Foil Stamping:

Foil stamping is often used in conjunction with embossing or debossing to create a more dynamic impression on your business card. They both require a die and adding heat and pressure. For these reasons, the two are often thought to be the same. However, foil stamping is just what it sounds: a thin film of metal. Embossing actually changes the surface of your card. You might be thinking, “why not just use metallic ink?” Well, you can do that, especially if you are trying to save money. Foil stamping just adds a little more pop to the design.

Foil stamping should be done on smooth, uncoated paper for best results. Textured papers such as linen or felt are more difficult because the uneven surface interrupts the pressing process. It’s also good to avoid using coatings or varnishes in the area to be foil stamped. Because foil stamping requires a die, the finishing is on the pricier end of finishing options.

3. UV Coating:

UV coating creates a very glossy, shiny coating on business cards and other papers. UV coating is great for business cards with images, as it makes details pop and stand out. If the image has blues or blacks, the end result is an almost wet appearance. UV coating helps protect your card against both chemicals and abrasions due to its hard finish. BONUS: It’s also environmentally friendly! UV Coatings are solvent-free and do not emit volatile organic compounds (VOCs) during the production process.

It’s a little bit hard to convey in photographs, but do you see how the light reflects off the business card below because of its high shine?

One disadvantage of UV coating is it catches and shows oil more easily, such as fingerprints. It can be wiped off, but it’s something to consider. UV coating should not be used on metallic inks, foil stamping or anything that needs to be written on. For this reason, some clients will have only one side of their business card UV coated. Lots of people like to write on business cards, so it’s smart to keep one side uncoated.

You can either spot or flood UV coat a paper. Spotting is using the coating only on certain areas or “spots” of the paper. We don’t do this in our office. Flood UV coating is covering the entire business card. The card above is flood UV coated.

4. Die Cutting:

Die cutting is another amp favorite. Die cutting is essentially making your business card (or other paper material) into a shape. A unique and fun way to make your business card memorable. Die cutting, as it implies, requires a die to be made, which ups the price. However, ask your local print shop what dies they have in-store. They may already have a business card in the shape of a rhomboid!

Insider tip: round-corner business cards are an easy way to make your business card look more unique and professional. At amp, it is one of our “rush” options because we can do fewer than one hundred cards by hand. However, if you need more than 100, the business card will require its own die.

5. Folding:

Folding is just what it sounds like. Business cards can have a fold to add more space (and more copy) and/or a unique design. As business cards are printed on cover weight, they will need to be scored in order to be folded. Scoring is any method of reducing paper stiffness along a line in order to aid in folding. We use a machine to do this for us, which speeds up the process.

6. Lamination:

When most people think of lamination, they think of sealed-edge lamination, such as the kind found on menus. This isn’t always pretty, but it protects the material from water, dirt and abrasion. Flush-cut lamination is more commonly used with business cards, as it offers some degree of protection but still looks nice. As business cards have a shorter life-span than menus, flush-cut lamination makes sense.

There are several different types of lamination, including matte, gloss and soft-touch. Yes, there are matte and gloss papers, as well. Matte and gloss lamination just add another protection layer. Textured paper should not be laminated as it would lose its tactile nature, thus defeating the purpose of the unique card. Soft-touch is one of our favorites. If you select this type of lamination, you will want to hold your business cards all day! Below are pictures of the different laminates, although in the case of soft-touch and matte lamination, it is almost impossible to see. However, for some people, that is the best part. It doesn’t look like a laminate, but it has the feel and protection of a laminate.

If you decide you want to laminate your business card, you will need to decide the thickness of the laminate. 10-mil is a very thick laminate, as shown in the Platinum business card below. Compared side-by-side to a plastic business card, the thicknesses are roughly similar. 3-mil would be a very thin laminate, but it would still protect your card. You should ask your printer for samples to see what thickness you prefer.